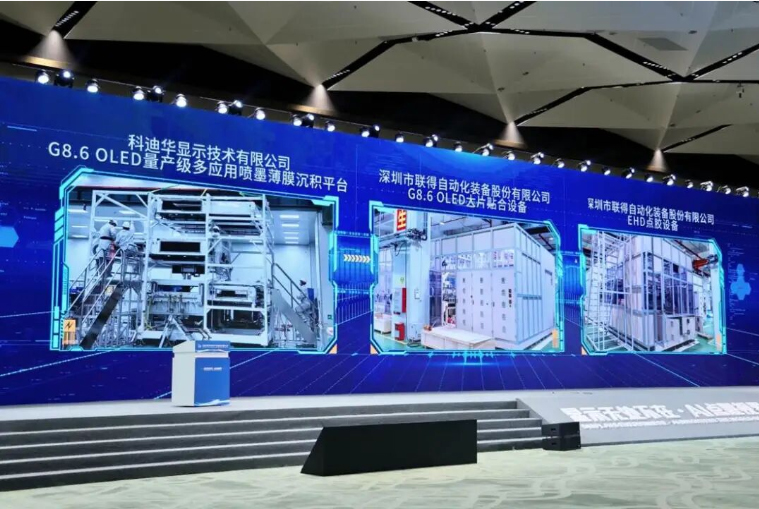

It is understood that the three high-end equipment launched in the display field this time are Corteva's multi-application inkjet thin film deposition platform, Liande Equipment's first domestically produced large-panel lamination equipment and the first domestically produced EHD dispensing equipment, all of which are applied in the mass production lines of 8.6th-generation large-size OLED screens.

It is reported that Corteva's G8.6 OLED mass production-level multi-application inkjet thin film deposition platform has reached the international leading level in terms of printing accuracy and production efficiency, and can meet the large-scale mass production needs of the industry. Its innovative printhead combination module supports the entire process chain from high-precision patterning to pixel deposition, providing a complete solution for the OLED industry. The launch of this platform will effectively help China achieve mass production of OLED with larger size, higher efficiency and lower cost.

Liande Equipment's G8.6 OLED large-panel lamination equipment has achieved a breakthrough for domestic equipment in the EAC segment lamination protection process for the first time, effectively preventing damage to OLED panels during the manufacturing process, providing critical support for panel yield and ensuring the independent controllability of the industrial chain Shenzhen Liande Automatic Equipment Co., Ltd. The EHD dispensing equipment adopts innovative electrohydrodynamic (EHD) technology, featuring ultra-narrow line width of 10-micron level and excellent irregular-shaped filling capability, demonstrating outstanding performance in high-end application scenarios such as ultra-narrow bezels, realizing the mass production application of this technology in China for the first time, with technical indicators reaching the industry-leading level.

Hu Chunming, Executive Deputy Secretary-General of the LCD Branch of the China Optics and Optoelectronics Manufacturers Association, stated that the launch of these high-end domestic display equipment will help China achieve mass production of new display products with larger size, higher efficiency and lower cost, marking that China's display industry manufacturing equipment is moving towards a new stage of localization and high-endization.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

Suzhou Fuheng Automation Technology Co., Ltd. is currently a professional company in China that focuses on the application research, promotion, and technical support of precision dispensing systems such as MARCO, VERMES, V-SMART, EFD, San-Ei (Japan), and Musashi in industries including semiconductor packaging, biopharmaceuticals, precision electronics, fingerprint recognition, and camera display touch modules.

As a professional service provider for precision dispensing applications, our company has assembled a team of over 30 professionals in automation, materials, software vision, and precision dispensing applications, and operates professional application verification laboratories in Suzhou, Shenzhen, and other locations. We have successfully cooperated with equipment vendors and directly provided secondary replacement services to end customers for professional projects at enterprises such as GIS, Samsung, LG, OPPO, Huawei, Tianma, BOE, HiSilicon, and Orbita.