The Role of Micro-Dispensing in Automotive Manufacturing

In the automotive manufacturing industry, manufacturers and upstream and downstream suppliers must balance production efficiency and processing precision while meeting stringent production standards, facing dual core challenges. Micro-dispensing technology—the high-precision, quantitative application process for minute amounts of adhesives, sealants, greases and other functional fluids—imposes extremely high requirements for precision control and process management, serving as a key link to ensure the manufacturing quality of automotive components.

As regulations across the global automotive industry become increasingly stringent and consumer expectations for vehicle quality, durability and safety continue to rise, the core value of precision micro-dispensing technology has become more prominent. It can not only enable seamless traceability of the production process and significantly reduce material waste, but also improve product reliability from the source of the process, helping enterprises meet compliance requirements and market expectations.

One of the core elements to achieve optimal performance of automotive components lies in the collaborative optimization of precision micro-dispensing and conventional dispensing processes. The functional materials used for bonding and sealing automotive components are often high-cost. Therefore, minimizing material consumption and ensuring repeatability of dispensing precision through process optimization can not only save substantial production costs for enterprises, but also effectively advance the implementation of green manufacturing and sustainable development goals.

By virtue of efficient and precise utilization of materials, micro-dispensing technology can effectively conserve resources and reduce the environmental impact of production processes. The high-precision micro-dispensing systems provided by Germany-based marco play a core supporting role in this process, enabling manufacturers to precisely apply the exact amount of adhesive required for each automotive component. This perfectly balances the requirements of precision, efficiency, cost and environmental protection, empowering the upgrading of automotive manufacturing processes.

Advantages of Micro-Dispensing in the Automotive Industry

Whether your application in automotive production requires micro-dispensing or high-volume dispensing, Germany-based marco offers high-precision dispensing solutions to optimize efficiency, reduce waste, and enhance durability. These advanced systems provide reliable and repeatable fluid application for a wide range of automotive components, including:

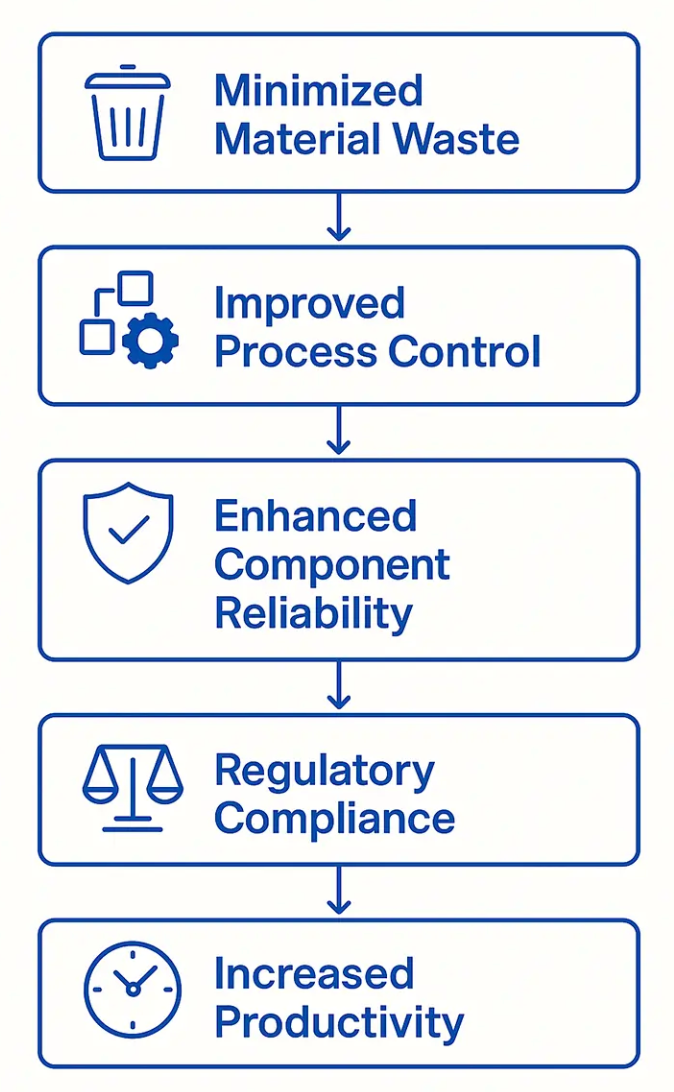

• Minimized material waste: Precision dispensing reduces the consumption of excess adhesives, sealants or lubricants, significantly lowering material costs.

• Improved process control: marco’s automated micro-dispensing systems ensure consistent application, minimizing errors and rework.

• Enhanced component reliability: Precise fluid application improves the durability and performance of vehicle components.

• Regulatory compliance: Seamless documentation ensures adherence to industry safety and environmental regulations.

• Increased productivity: Automated micro-dispensing cuts down cleaning and maintenance time, boosting overall efficiency.

marco Systems' Micro-Dispensing Solutions

With high precision, our micro-dispensing technology also reduces cleaning and maintenance efforts, meets requirements, saves time and further boosts productivity. In short, our solutions enable automotive manufacturers and suppliers to achieve reliable and cost-effective production, while meeting regulatory standards and customer expectations for quality.

By delivering consistent and accurate material application, Germany-based marco provides highly customized dispensing solutions for the automotive and transportation industries, which are designed specifically for the durability and precision required in critical applications. Examples include:

• Sensor manufacturing for the automotive industry: Precise dispensing plays a critical role in the accuracy and performance of road condition sensors. These sensors detect water on the road surface in real-time while driving, with measurements based on vibration detection using piezoelectric elements.

• Precision oiling and lubrication for gear assemblies (including sunroofs, brakes, gear teeth, and other mechanical components) to ensure smooth operation and reduce wear.

• Potting and encapsulation for high-reliability electronics such as GPS, engine controls, and HVAC systems, protecting sensitive components from environmental stress.

• Lubrication of plastic gears in rearview mirror motors to ensure quiet and reliable functionality.

• Grease dispensing for front axle mechanical components to enhance durability and reduce maintenance requirements.

marco Systems for Sensor Production

How Precision Dispensing Enhances Automotive Manufacturing Efficiency

Germany-based marco’s high-precision dispensing systems provide both micro-dispensing and high-volume dispensing solutions for manufacturers in the automotive and transportation industries, enabling them to produce products that deliver long-lasting performance and reliability even under extreme conditions.

Conclusion: Achieving High-Precision Dispensing in Automotive Manufacturing

As demands for precision, efficiency, and cost-effectiveness continue to rise, micro-dispensing is becoming an indispensable technology in the automotive industry. Whether applying adhesives, sealants, lubricants, or potting compounds, Germany-based marco’s high-precision micro-dispensing systems ensure optimal material usage, lower production costs, and enhance component durability.

To learn more about how Germany-based marco’s micro-dispensing solutions can individually transform your manufacturing process, contact our experts today!