Why is Micro-Dispensing Technology Indispensable for Modern Medicine?

In the field of medical technology, dosing valves play a critical role in precise micro-dispensing (such as greases, silicone oils, or UV adhesives).

Typical application areas include:

• Lubricating the dispensing devices in auto-injectors such as insulin pens.

• Assembling syringes or needles with UV adhesives.

• Siliconization of injection needles or spray components for nasal spray bottles.

These high-precision processes enable the reliable operation of equipment essential for patient care. It is expected that the demand for micro-dispensing technology in the medical technology sector will grow steadily in the coming years.

Needles, Wearables, or Surgical Instruments: The Applications are Diverse

Whether for implants such as pacemakers, wearable devices like insulin pumps and hearing aids, or the manufacturing of surgical instruments, micro-dispensing is crucial for the bonding and processing of precision components. The use of biocompatible media is becoming increasingly important.

Under-dosing can compromise component stability, while over-dosing can lead to malfunctions. This is particularly critical in the production of wearable devices, where minute amounts of adhesive must be dosed precisely to avoid damaging sensitive electronics.

Another application is coating surgical instruments with protective layers or lubricants to enhance their performance and reduce infection risks. Experts estimate that approximately 90% of surgical instruments are coated with special layers or lubricants during the production process. (Source: Medical Device Manufacturing Magazine, 2021).

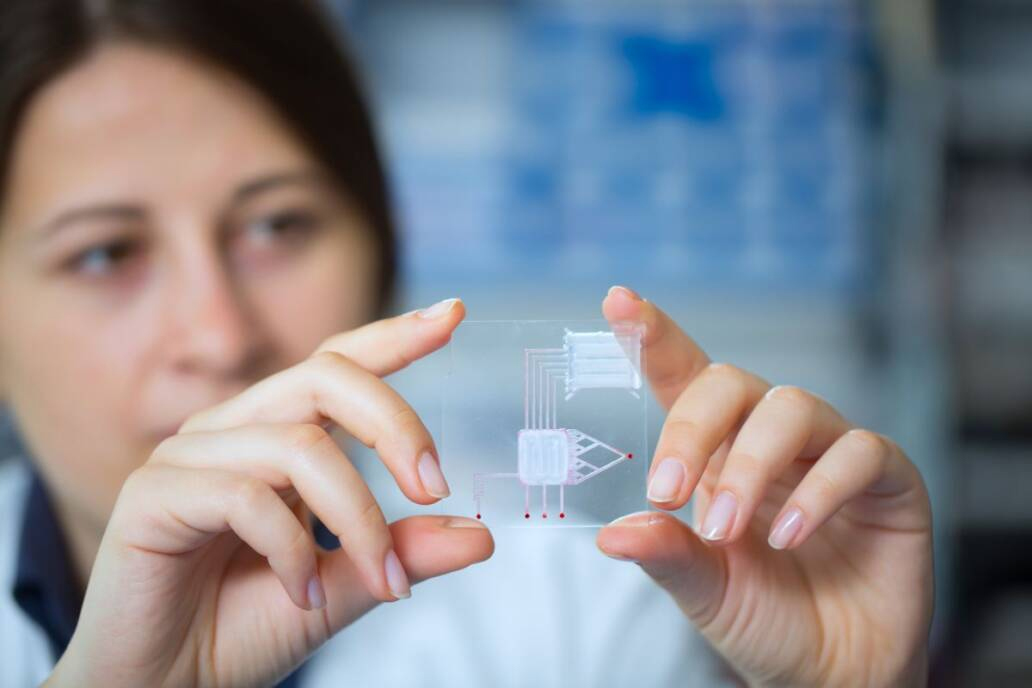

Microfluidics and Lab-on-a-Chip Technology

Microfluidic chips and lab-on-a-chip systems also benefit from micro-dispensing. These technologies enable minimally invasive diagnostics and treatment.

Thanks to the extremely high precision of micro-dispensing, fluids of just a few nanoliters can be precisely dispensed. This facilitates the miniaturization of medical devices, which is particularly important for patient care. (Source: rsc.org; Alleima - Miniaturization of Medical Devices).

How Micro-Dispensing Precisely Achieves Fine Structures

The piezoelectric technology of non-contact jet dispensing is particularly noteworthy, as it enables extremely fast and precise dispensing processes. Despite these advantages, many production systems still rely on contact dispensing processes. In these applications, dispensing needles are positioned close to the target surface to deposit materials.

Contact Dispensing Also Has Its Advantages

A typical example of the contact dispensing process is the processing of glass sleeves. Here, multiple sleeves are processed simultaneously, with dispensing needles moving in close contact with the components and droplets being precisely wiped off. This method is ideally suited for applications with well-defined geometries.

Non-Contact Dispensing for Complex Geometries

On the other hand, non-contact jetting offers distinct advantages for complex components, intricate geometries, or shorter cycle times. This is especially true for components with structured surfaces, such as the grooved shafts in retractable syringe systems. Jetting dispensing truly shines in such scenarios, as it enables direct deposition of liquids into fine structures without causing mechanical damage. Thanks to this versatility, non-contact jetting based on piezoelectric technology is the preferred solution for dispensing applications with extremely high speed and precision requirements.

Sustainable Dispensing Solutions: Trends in Medical Technology

A notable trend is the use of UV-curable adhesives. They offer significant advantages:

• Reduced production time: UV adhesives cure within seconds.

• Lower energy consumption: Low-power LED lamps are sufficient to initiate the curing process.

Switching to UV adhesives improves efficiency and shortens production time. Production costs are also reduced by eliminating the need for ovens, saving energy and production space.

Demographic Changes and Growing Demand

Demographic shifts are having a significant impact on medical technology. By 2050, the global elderly population is expected to increase by 60%. Longer life expectancy and the rise in chronic diseases will continue to drive the demand for medical products. The need for devices such as syringes, diagnostic systems, and infusion sets will see sustained growth. Disposable products will play a key role, already accounting for 65% of medical device sales. (Source: World Health Organization Report, 2022).

Micro-Dispensing and Laser Welding: A Powerful Combination

Micro-dispensing and laser welding complement each other perfectly in the manufacturing process of medical devices. Micro-dispensing is often used prior to laser welding to precisely apply liquid fillers or protective materials, thereby optimizing weld quality. Particularly in microsystem technology—such as in the manufacturing of microfluidic chips—these two technologies go hand in hand: liquid reagents are precisely dosed before the chips are sealed via laser welding.

Is This a New Trend?

Micro-dispensing and laser welding are not entirely new technologies, but they have received a significant boost in the field of medical technology.

In recent years, the focus on miniaturization, biocompatible materials, and maximum precision has made these processes particularly popular. According to market analysis by Statista, the demand for laser welding systems in the medical technology sector has increased by 40% since 2018. (Source: Statista, 2023). It is foreseeable that this trend will continue to gain importance.

How Micro-Dispensing Exerts a Lasting Impact on Medical Technology

In conclusion, these developments indicate that medical technology is not only a promising industry, but also one that is constantly evolving thanks to innovative technologies such as UV-curable adhesives and the ever-growing demand for medical products. Marco Dispensing Systems is at the forefront of this expanding market with efficient and sustainable solutions that are perfectly tailored to the industry’s requirements.

Benefiting from continuous R&D, we are making steady progress in dispensing and production technologies. These innovations not only enable us to meet the complex requirements of medical technology, but also make the production process more efficient. Whether in the manufacturing of spray systems, needle systems or specialized medical devices, our solutions set new standards for quality and precision, and open up groundbreaking prospects for the industry.