Precise Dispensing Systems

With its highly developed dosing systems, [Company Name] offers solutions that meet these requirements. These systems enable precise, economical material processing, reducing waste and increasing processing speed without compromising quality. Especially in critical aerospace applications, these systems are essential for ensuring maximum reliability and performance.

From Structural Bonding to Cavity Sealing - Dispensing Technology for High-Demand Missions

In aerospace technology, precise dispensing processes are crucial to ensuring maximum safety, durability and performance. Applications such as bonding structures, sealing edges, filling cavities, and sealing riveted or bolted components can protect precision components from environmental influences and mechanical stress, enabling them to operate reliably.

Every Dispensing Application Is Unique – Marco Systems Delivers the Solutions

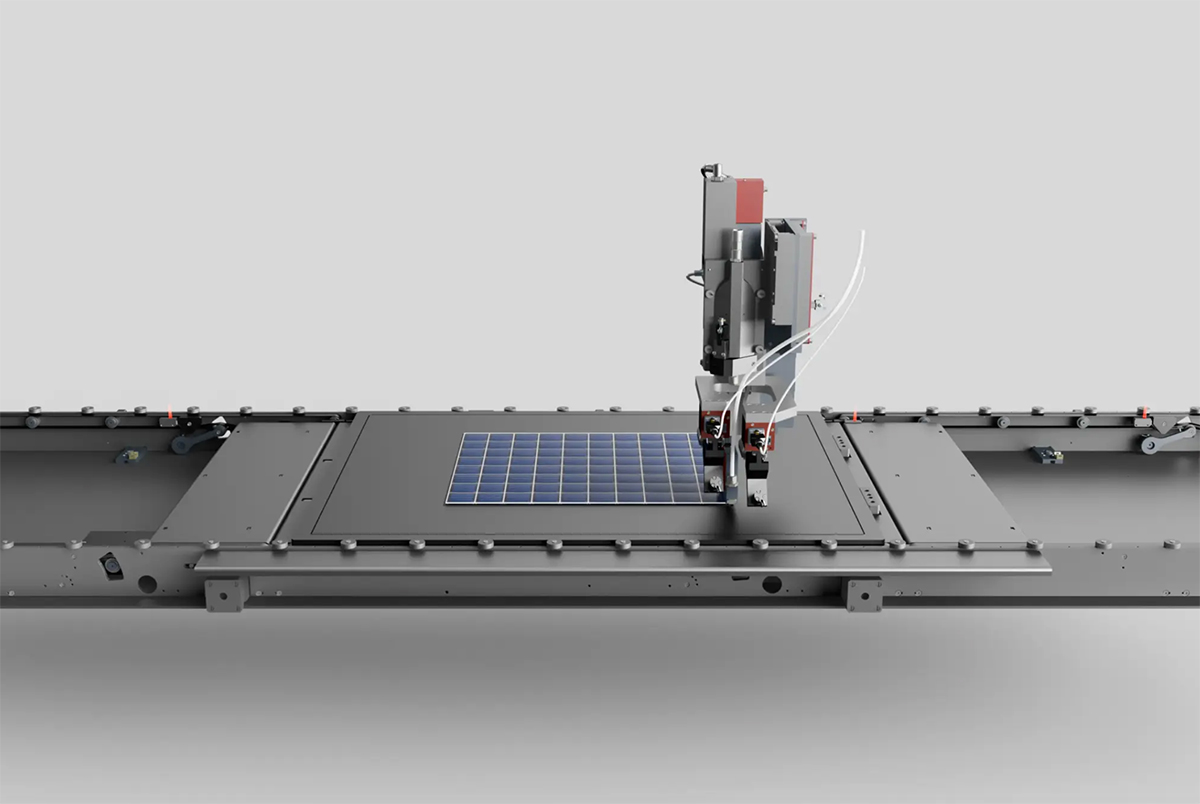

• Bonding and mounting space-qualified solar panels to ensure durability under extreme conditions.

• Encapsulating sensitive electronic circuits for protection against environmental factors.

• Providing EMI-RF shielding for stealth devices and instruments to ensure signal integrity and security.

• Potting and encapsulating components exposed to extreme environments.

• Enabling efficient heat dissipation with thermally conductive materials.

• Dispensing metal-filled products to enhance their structural and conductive properties.

• Metering flux via jetting technology for precise, high-efficiency soldering in high-reliability components.

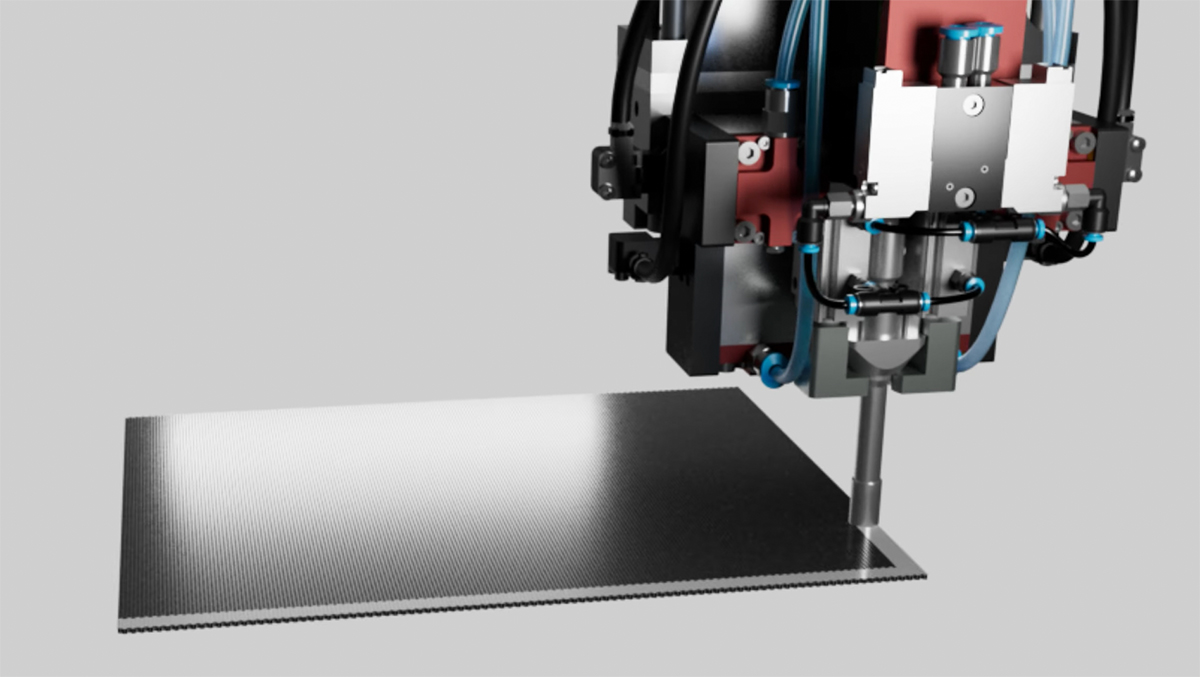

Filling honeycomb patterns with 2K mixing heads

Micro-dispensing for these customized aerospace applications enables manufacturers to meet the highest standards of precision, durability, and efficiency—critical for the safety, reliability, and performance of space and defense systems.

Micro-dispensing for satellite solar panel mounting is a particularly challenging, specialized application. Read our article and watch the video.

Do you have any questions about our micro-dispensing solutions for aerospace technology? Or do you need some advice? Our team of experts is ready to answer all your questions—please contact us!