The innovative marc1 platform system, that is, a dispensing robot, can navigate precise path curves along all axes. It is capable of dispensing minimal amounts of solder paste, silver adhesive, underfill and other materials. The marc1 platform system achieves precise synchronization of dispensing and movement via the Dispensing Control Unit (DCU), integrating state-of-the-art robotics with sophisticated dispensing control. This is unparalleled in the dispensing industry.

Boasting a robust yet lightweight structure, it offers a tool load capacity of up to 7 kg and enables precise high-speed dispensing with acceleration up to 3g, with dispensing processes infinitely repeatable. The marc1 robotic system delivers complete solutions for diverse applications. It features an extra-large working area paired with a highly compact work surface. Equipped with a large, rotatable HMI touchscreen and a retractable keyboard, it ensures simple and convenient operation.

All five linear motors on the three axes are equipped with a newly developed patented water cooling system.

This intelligent thermal control system ensures temperature stability, enabling consistent high-precision dispensing throughout the entire process.

The large glass door at the front of the equipment facilitates operation, while the left and right openings are suitable for integration into inline production lines (with interfaces compliant with SMEMA standards). The rear opening design is intended for cluster arrangement of equipment. The robot is also suitable for use in clean rooms.

Thanks to its modular design, the marc1 robot adapts to customers' evolving needs, such as medium, air and cooling water supply. A large number of pneumatic and electronic interfaces are pre-installed on the unit and bed to enable quick integration of other units and tools.

* Maximum acceleration of all axes: up to 3g Repeatability: ±3 μm

* Dimensions (mm) L/W/H: 800 x 950 x 1800

* Axis travel range X/Y/Z (mm): 480 x 480 x 120

* Lightweight structure: basic version weight 650 kg

* Opening dimensions for cluster or inline configuration (mm)Front door

- opening: 640 x 520 (L x H)

- Side door opening: 460 x 190 (L x H)

- Rear door opening: 445 x 185 (L x H)

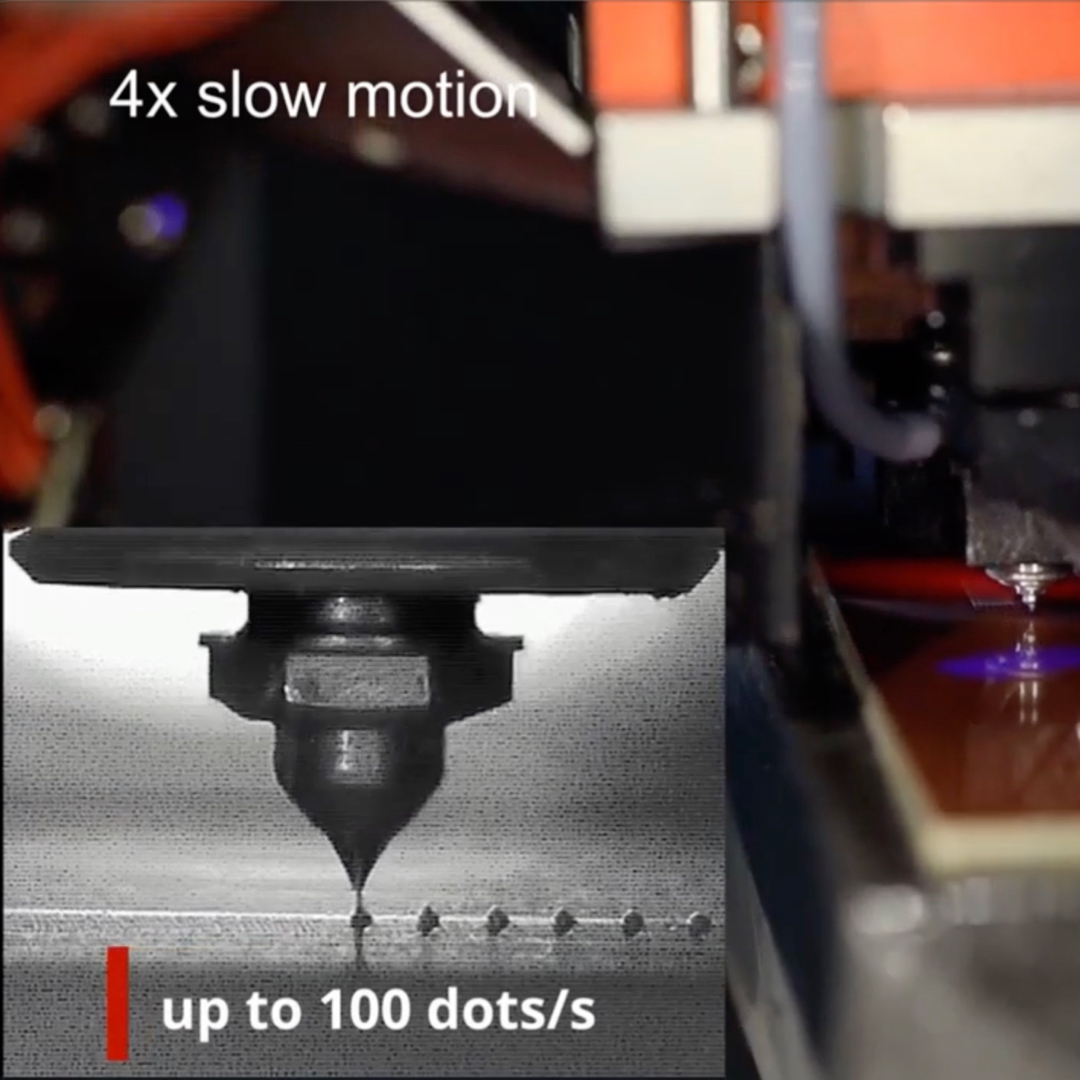

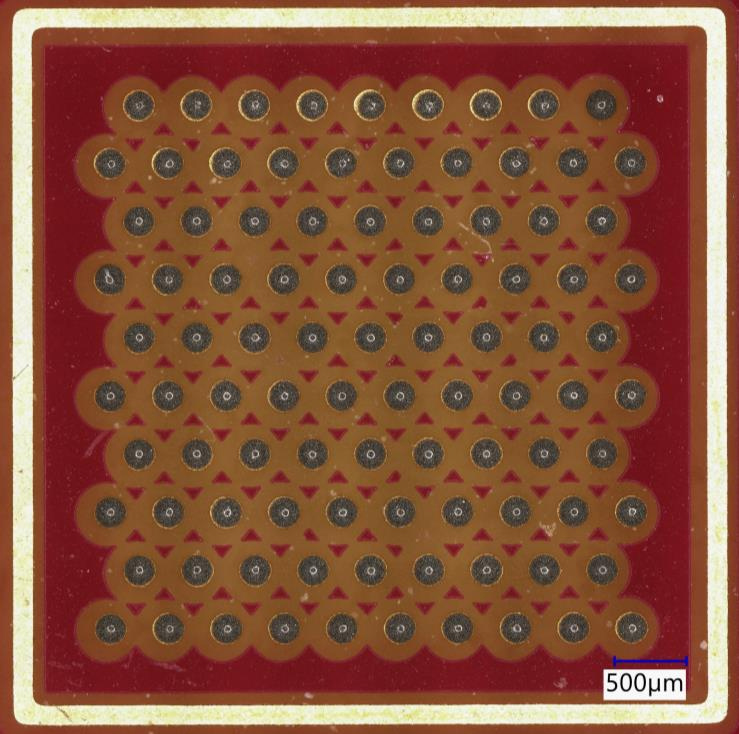

Actual Solder Paste Dispensing Effect Diagram

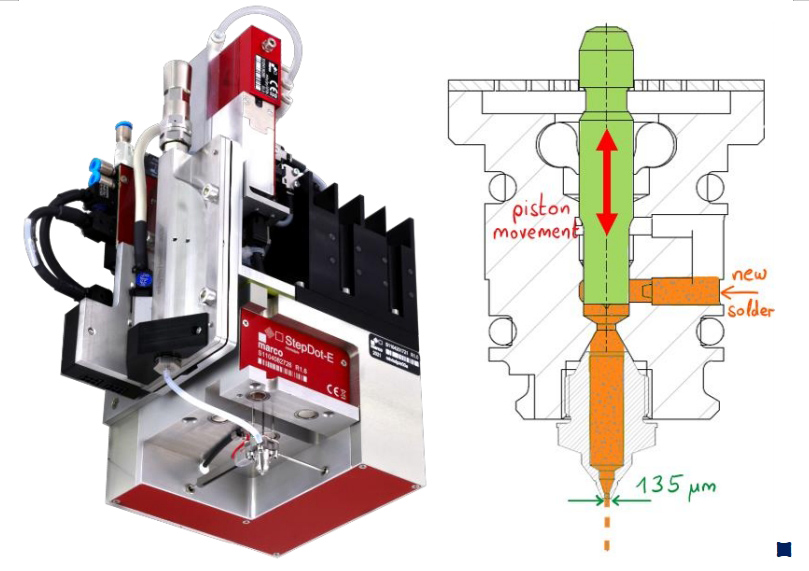

The following are only partial examples. Piston-type cartridges are available in multiple specifications: 300 μm/500 μm and 1000 μm.

• These piston-type cartridges are compatible with both StepDot and sJet nozzle systems.

• Threaded nozzles also come in a wide range of specifications, with a minimum aperture of 50 μm.

• Contact dispensing achieves 100% satellite-free dots.

Data Download

Data Download

0512-6729 6366

189 1261 4422