Location:Home > Marco Dispensing Consumables & Accessories

The Piezo jet valve features a modular design where the part in contact with the fluid is designated as the Valve Seat, and the part not in contact with the fluid is the Drive Unit. As the flow channel for the fluid, the Valve Seat directly affects the flow velocity and volume.

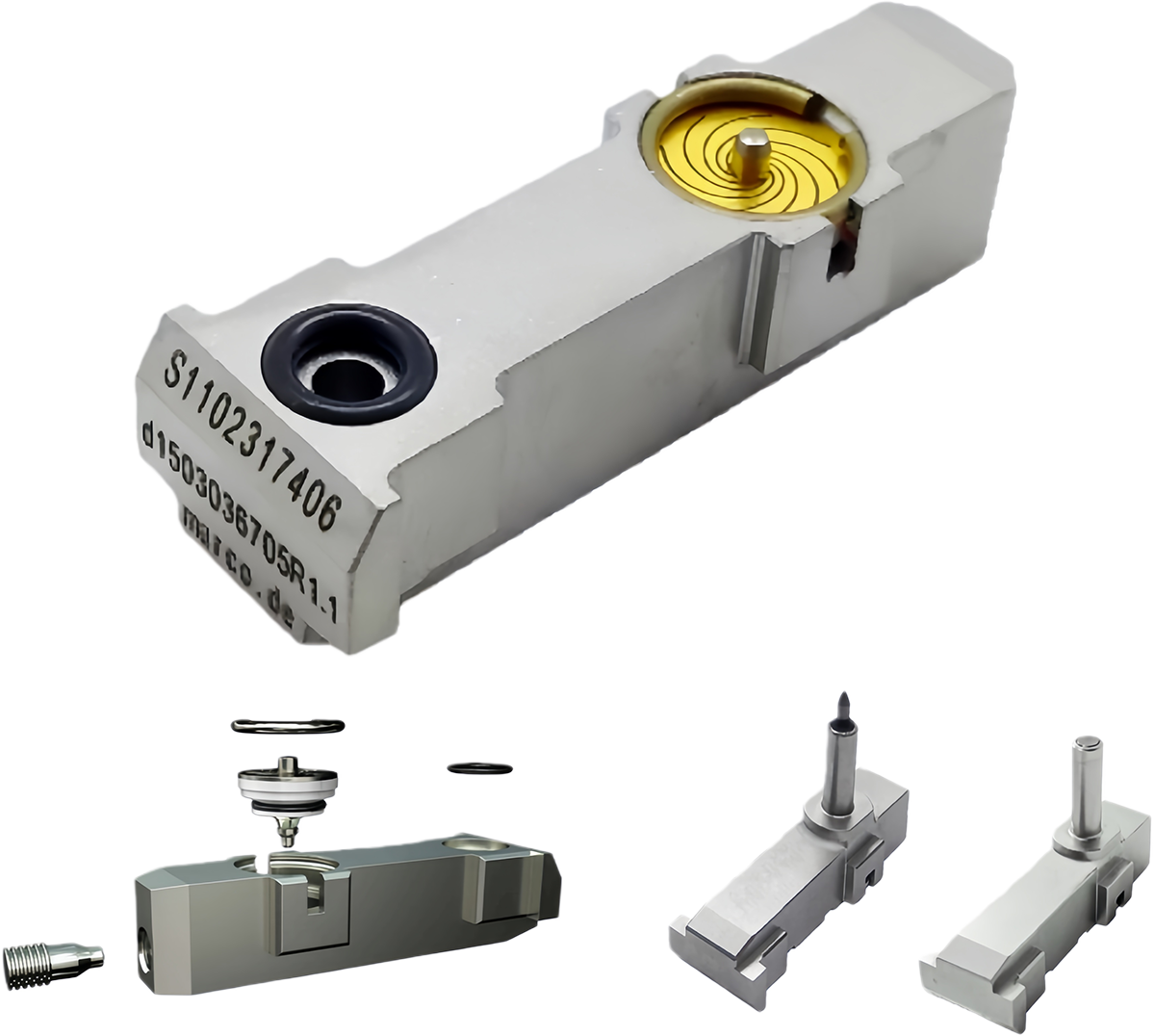

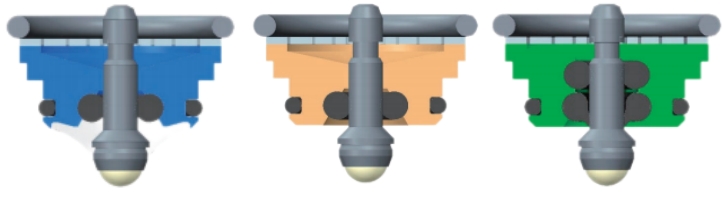

The Valve Seat consists of the Seat Body and the Valve Core. The Seat Body is available in metal or polymer materials (specifically for anaerobic adhesives). Valve Seat nozzles come in a series of diameters (ranging from 40µm to 800µm) and are categorized into Flat Jet, Needle, and Extended types. It is essential to select the appropriate Valve Seat type to meet dispensing requirements in different applications.

The Seat Body requires regular cleaning in an ultrasonic cleaner. The Valve Core must not be soaked in organic solvents. A dedicated tool should be used to clean the nozzle to prevent damage. When fluid crystals accumulate on the sealing surface of the Valve Seat, do not use sharp objects to remove the crystalline layer, as this will scratch the sealing surface.

To prevent fluid from crystallizing, solidifying, or causing blockages inside the Valve Seat, please consult with Fuheng Technology's technical staff to select the correct Valve Seat for your specific application.

Driven by the ram of the piezo jet valve, the valve core opens and closes the fluid channel, cuts off the fluid and accelerates it for jetting. The valve core adopts a helical spring reset mechanism. The plunger of the valve core and the ram of the valve body are engaged for integrated movement. The dynamic seals are divided into lip seal type and double-seal type. The ceramic balls of the valve core are available in two diameters, Type B and Type D, which are suitable for low-viscosity and high-viscosity fluids respectively.

The valve core requires regular cleaning and must not be soaked in organic solvents to avoid dissolving the lubricating oil inside. A special tool must be used for disassembling the valve core to prevent damage.

The sealing rings and helical springs included in the valve core are consumable parts and need to be replaced regularly to ensure the valve core operates in optimal condition.

For different applications, the valve core should be equipped with suitable ceramic balls, sealing types and sealing materials. Please consult the technical staff of Fuheng Technology when selecting the valve core.

Data Download

Data Download

0512-6729 6366

189 1261 4422