Micro-dispensing System – Nozzle Unit + Nozzle

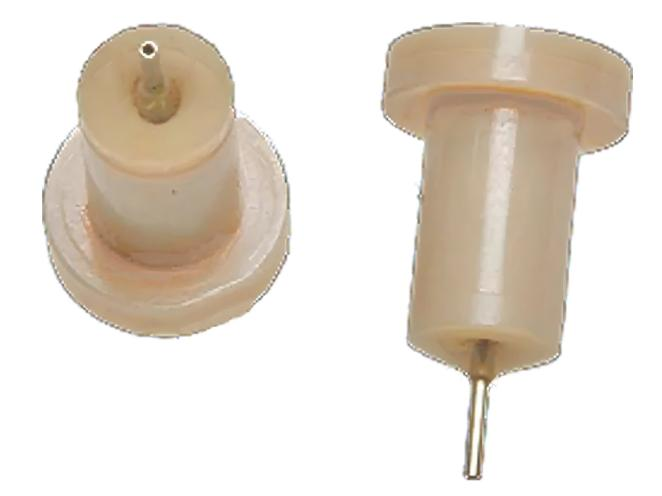

Nozzle Unit and Nozzle

Applicable to MDS 3000 Series and MDS 1000 Series

You can select the most suitable type for your application from a range of nozzles provided by VERMES. Whether it is non-contact or contact dispensing, regardless of dispensing volume, whether it is filling or non-filling dispensing, and whether it is for low, medium or high viscosity media, there is always a nozzle suitable for your application at VERMES.

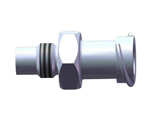

The nozzle unit is one of the core modules of the micro-dispensing valve, which is used to mount the nozzle and position the plunger. The nozzle unit includes:

Nozzle Adjustment Nut

Plunger Guide Ring

O-ring Seal

It is also used for mounting nozzles. Some components of the nozzle unit are in direct contact with dispensing media. To meet the compatibility requirements of various dispensing media, we provide nozzle units made of different materials.

When a top-calibrated dispensing valve is used with fluid cartridges MDFH-48-CH-TA (MDS 3250+FC) or MDFH-48-CH-BY (MDS 3280 and MDS 1560), the nozzle retaining nut shall be used instead of the nozzle unit. Unlike the nozzle unit, the nozzle retaining nut consists of only one component and does not require the use of a plunger guide ring or an O-ring seal.

The nozzle adjustment nut is part of the nozzle unit, with a range of different models available.

Nozzle Adjustment Nut NAN-fix-H

Nozzle Adjustment Nut NAN-fix-H+10

Nozzle Adjustment Nut NAN-fix-HC

Nozzle Adjustment Nut NAN-fix-HC+10

Nozzle Adjustment Nut NAN-fix-L

Nozzle Adjustment Nut - Universal

Nozzle Adjustment Nut - MDH 230tf

Nozzle Adjustment Nut - Universal +10

Nozzle Adjustment Nut - Needle Protection

Nozzle Adjustment Nut - MDH 230tf +10

The plunger guide ring is part of the nozzle unit and guides the plunger precisely into the nozzle. The plunger guide ring comes with a Nitrile (NBR) O-ring as standard. Seals made of other materials are also available, such as EPDM, FKM, or Silicone.

The MDS 3000 and MDS 1000 dispensing systems adopt a modular design, allowing quick installation of different components to meet various application requirements. In addition to the selection of components such as dispensing valves, fluid cartridges, nozzles and plungers, consideration of the compatibility of seals and seal materials is also crucial.

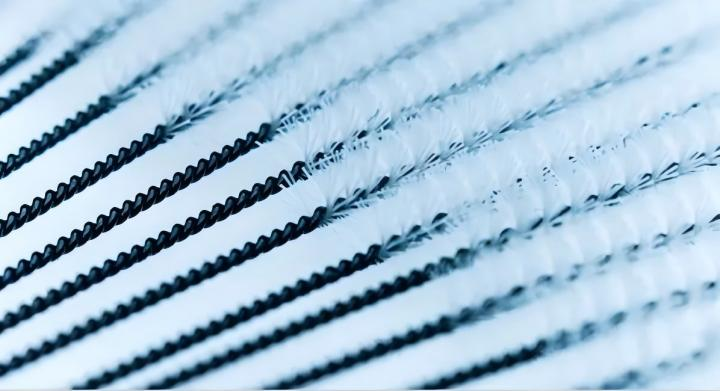

The Type N Nozzle is the most commonly used among all nozzles, with a range of sizes available.

Features:

The jet orifice is close to the dispensing substrate

Meets diverse parameter requirements

Easy to operate

A wide selection of sizes and shapes available

Multiple versions of internal nozzle channels are offered (stepped and tapered)

A broad range of nozzle lengths from 1.75mm to 4mm available

A wide range of nozzle groove outer ring diameters from 30 μm to 1200 μm available

Precision-manufactured with accurate specifications

Reusable, reducing downtime and material loss

Delivers precise dispensing results in complex applications, such as LED potting, underfilling and edge sealing

The laser-marked serial number contains multiple digits, enabling efficient traceability and control

Reduces back pressure to ensure sufficient dispensing

Durable even when used with abrasive or particle-containing media

Dot size can be as small as 50 μm

Type J Nozzle is mainly used for long-distance dispensing or groove filling. A wide range of models are available.

Features:

Can jet media onto substrates over long distances

A wide selection of sizes and shapes available

Multiple versions of internal nozzle channels are offered (stepped and tapered)

A broad range of nozzle lengths from 1.75mm to 4mm available

A wide range of nozzle groove outer ring diameters from 30 μm to 1200 μm available

Single-row or double-row conical shape

Can jet dots, lines or special patterns, eliminating dispensing stringing/tailing

Delivers precise dispensing results in complex applications, such as LED potting, underfilling and edge sealing

The laser-marked serial number contains multiple digits, enabling efficient traceability and control

Long nozzle tip design, especially suitable for jetting media into hard-to-reach areas

The Type C Nozzle is made of PEEK (Polyether Ether Ketone) and stainless steel, making it particularly suitable for medical applications involving low-viscosity media.

Features:

The Type C Nozzle is made of PEEK and HM, paired with a stainless steel tube

The stainless steel tip features a precision-finished stainless steel tube

Can jet media onto substrates over long distances

Best suited for low-viscosity media applications

Non-metallic nozzles are particularly suitable for medical industry applications

Type P Nozzle is specially designed for angled dispensing.

Features:

Constructed of metal and plastic

Especially suitable for angled dispensing (90°, 80°, 70°)

The inner layer of the Type P Nozzle is replaceable, which helps reduce costs

After dispensing with corrosive or self-curing media, it is recommended to thoroughly clean the system, including the dispensing valve and other components in contact with the media.

The surface of the dispensing valve is prone to wear. Do not use wire brushes or other inappropriate tools. VERMES offers a range of specialized cleaning tools, such as the CTK Cleaning Kit, which includes a series of essential tools for system assembly/disassembly and cleaning. Our experts are available to provide you with professional advice.

Please feel free to consult Fuheng Technology for cleaning tools and methods. We are happy to assist you.

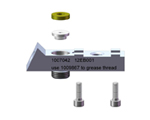

This tool allows nozzle cleaning grease to be forced through the nozzle channel under high pressure to clear clogged flat-shaped carbide nozzles. VERMES Dispensing Technology recommends the use of Nozzle Cleaning Grease HP1 (one piece included in the tool package). This tool is only suitable for nozzles with an orifice diameter smaller than 100 μm.

This tool is equipped with a nozzle insertion port and can be used to secure nozzles.

Once the nozzle is secured, the nozzle will not be accidentally blown away when cleaning it with compressed air.

This kit is used to clean components that have come into contact with dispensing media (such as fluid cartridges, cartridge holders, and Luer connectors).

The kit includes:

25 cleaning swabs

20 cleaning sticks

20 cleaning brushes

This tool is suitable for nozzles with an orifice diameter of 100 μm or larger, and can be used to clear nozzle channels. Nozzle Cleaning Needles are available in different sizes, distinguished by color.

Available Nozzle Cleaning Needle Sizes:

Size 100 – Size 500

This kit is used to clean nozzles with an orifice diameter of approximately 70 – 400 μm.

The kit includes:

6 nozzle cleaning drill needles

Applicable to MDS 3000 and MDS 1000 Series

All VERMES dispensing systems can be equipped with optional heating blocks. There are two main types of heating blocks: nozzle heating blocks and cartridge heating blocks. Cartridge heating blocks are commonly used in hot melt adhesive applications. Heating can alter the dynamic viscosity of the medium. Heating blocks are essential when dispensing must be performed at a constant temperature or above room temperature. A heating program that meets dispensing requirements is crucial for achieving accurate and repeatable dispensing results.

Integrated or stand-alone nozzle heating blocks can be selected according to requirements.

The integrated nozzle heating block is part of the MDFH fluid cartridge. In addition, VERMES provides heating block controllers that can adjust specific parameters according to different applications.

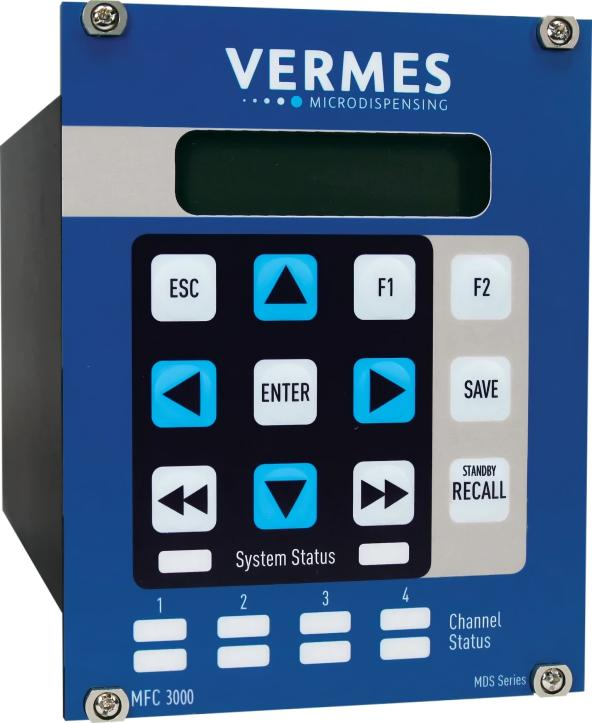

MFC 3000

The Multifunctional Controller MFC 3000 can perfectly control the dynamic viscosity of the medium in most complex applications. Through the control of heating and cooling, the system can maintain a constant temperature throughout the dispensing process. This controller is commonly used in hot melt adhesive applications, and is also suitable for high-precision dispensing applications with certain cooling requirements.

The Multifunctional Controller MFC 3000 can control the integrated heating blocks and compressed air valves connected to the VERMES dispensing system, with extremely low voltage requirements (24 V or 48 V). It can control up to four integrated heating blocks or cooling valves simultaneously, and the configuration can be flexibly adjusted according to specific requirements:

Heating only

Cooling only

Heating and cooling simultaneously

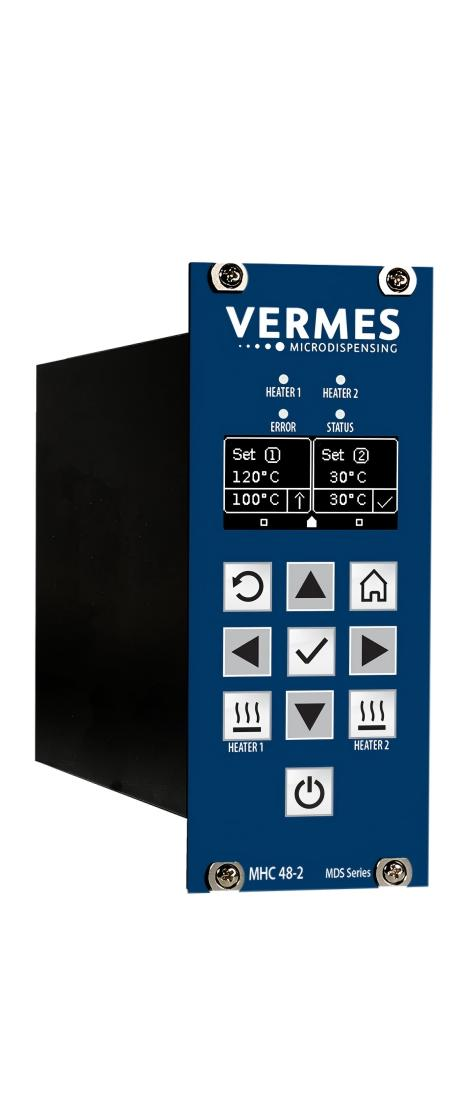

2-Channel Controller with Precise Temperature Control

During the dispensing process, the MHC 48-2 ensures the most accurate dispensing results through extremely precise temperature control.

This 2-channel heating block controller is specifically designed to control all 48V heating blocks provided by VERMES, such as nozzle heating blocks (fluid cartridge components) and cartridge heating blocks, which operate at ultra-low voltage.

The MHC 48-2 controller is a highly effective solution when only heating is required (e.g., using a nozzle heating block to ensure a stable temperature of the dispensing medium, or dispensing at temperatures above room temperature).

It is also the ideal choice when using both a nozzle heating block and a cartridge heating block simultaneously in hot melt adhesive applications.

The controller features a clear and concise user interface and offers automatic start-up, further simplifying operation and saving time.

Welcome to discuss suitable heating/cooling systems for your applications with Fuheng Technology. We are happy to help you find the optimal heating solution that best meets your requirements.

The fluid cartridge serves to transfer dispensing media from a syringe or pressure tank to the nozzle. Cartridges are available in different materials and models, such as left-angle/right-angle versions. There is thermal insulation designed between the fluid cartridge and the drive system.

The commonly used component for media supply is a syringe, available in different models (e.g., MDX 3080 CC/10 paired with a 10ccm syringe).

For applications requiring media heating, fluid cartridges with integrated heating blocks are also available.

The "Quick-Release Fluid Cartridge" features a unique design utilizing innovative connection technology. It can be easily detached from the dispensing valve with a simple flip of a latch, eliminating the need for screws or tools, making cleaning convenient and operation easy. Furthermore, the rotatable design allows the dispensing valve to flexibly adapt to different dispensing directions, enabling quick and seamless integration into any compact space.

What optional configurations are available?

Fluid Cartridge with Integrated Syringe Adapter

Fluid Cartridge with Hose Connection

Fluid Cartridge Shapes:

Inline, Left-Angle, Right-Angle, Double-Ended

MDFH Fluid Cartridge with Integrated Heating Block

MDFH-BY Fluid Cartridge with Removable Integrated Heating Block

FA Fluid Cartridge

Suitable for special media, such as cyanoacrylate or anaerobic adhesives

There are two types of fluid cartridge adapters available:

Syringe Adapters:

Materials: PEEK or Stainless Steel

Features: Luer connectors for fluid cartridges

Hose Adapters:

Materials: PEEK or Stainless Steel

Features: Suitable for hoses of different sizes

The VERMES dispensing system utilizes a modular design. Components that come into contact with the medium, such as nozzles, fluid cartridges, and supply units, are compatible with all dispensing valves provided by VERMES.

The fluid cartridge is connected to the valve with just two screws and can be cleaned separately. The Quick-Release fluid cartridge can be detached simply by flipping a latch, requiring no screws or tools.

MDX represents the supply unit of the VERMES dispensing system, whose main components are syringes and syringe holders. Syringes are available in different models with capacities ranging from 3 cm³ to 55 cm³, paired with corresponding syringe holders.

Plunger seals, plunger centering washers, set screws, and syringe adapters are all classified as fluid cartridge accessories. These components are generally available in different materials, such as stainless steel or PEEK.

We are happy to help you identify the optimal component combination for your application.

There are various ways to connect the medium to the fluid cartridge. We recommend using Luer connectors for syringe connections. For applications with larger dispensing volumes, hose connections are suggested.

For MDS 3000 and MDS 1000 Series

The plunger is one of the valve components that comes into contact with the medium and is mounted externally onto the valve.

Inside the valve, the plunger is connected to the Piezo actuator (MDS 3000 Series) or the DST actuator (MDS 1000 Series) via a lever. The force generated by the expansion/contraction of the Piezo is transmitted to the plunger through the lever, causing the plunger to move back and forth and eject the medium from the nozzle orifice.

The plunger, along with the nozzle, is considered a wear part. To achieve good dispensing results, the plunger must be regularly cleaned, lubricated, and replaced (approximately every 60 to 80 million strikes or when resistance to plunger movement occurs). For high-frequency dispensing applications, maintenance intervals may be longer.

If you need assistance with plunger selection, please feel free to contact Fuheng Technology. Our experts possess extensive dispensing experience and are happy to help you find the right plunger style. We offer plungers in different sizes, models, and materials to suit various dispensing media and applications.

Data Download

Data Download

0512-6729 6366

189 1261 4422