Designed for high-intensity applications, the PX2 Microdispensing System MDS 3583-FH delivers unparalleled precision and stability, and significantly extends the service life of piezoelectric components through advanced frame technology. Featuring an innovative bayonet-style fluid cartridge design, the system enables smaller, more stable and highly precise repeat dispensing performance ranging from the nano to sub-nano scale.

Powered by VERMES PX2 - Piezo Xtreme 2 Technology.

High-frequency heavy-duty system.

Exceptionally high repeatability.

Incorporates frame technology for outstanding stability and anti-expansion performance.

Integrated heating and cooling functions.

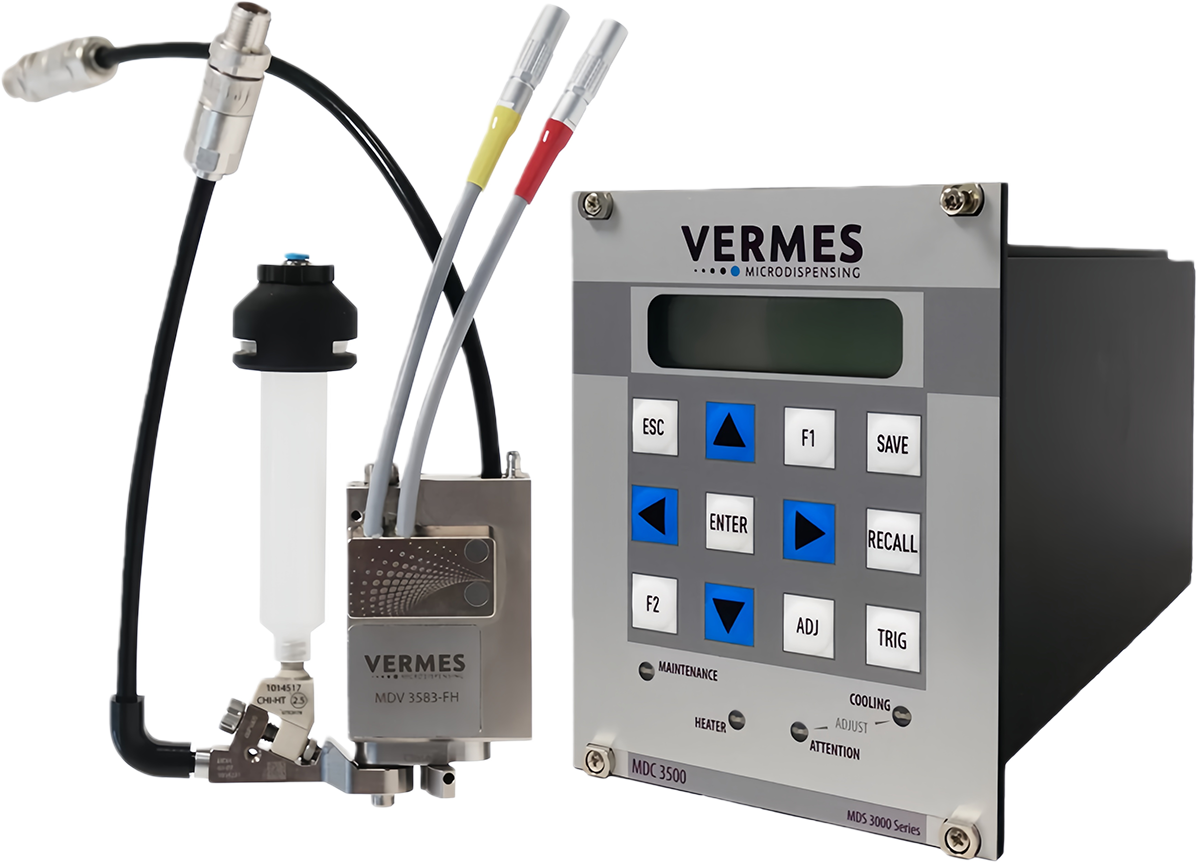

The MDS 3583-FH System from VERMES Microdispensing is engineered for superior quality, integrating advanced technology, versatility and outstanding performance to meet the highest industrial standards.

Powered by PX2 Technology: The MDS 3583-FH System adopts advanced PX2 technology to deliver unparalleled precision and control for microdispensing applications.

Integrated Heating & Cooling Functions: Equipped with integrated heating and cooling functions, the system ensures optimal fluid viscosity and stable dispensing performance regardless of ambient conditions.

High Compatibility: Fully compatible with all auger nozzles, valve cores and various spare parts, it meets diverse application requirements while offering excellent flexibility and ease of maintenance.

Innovative Bayonet-Style Fluid Cartridge Design: The MDS 3583-FH features an innovative bayonet-style fluid cartridge design, enabling quick and easy replacement of fluid components (plug-and-play) and significantly boosting operational efficiency.

Heavy-Duty Application Capability: Designed for high-frequency heavy-duty applications, the system ensures robust performance and long service life, making it the ideal choice for demanding industrial environments.

Equipped with PX2 technology, the MDS 3583-FH takes state-of-the-art microdispensing technology to new heights, enhancing dispensing precision especially for high-viscosity and ultra-high-viscosity media. It is suitable for a wide range of applications with various fluids, including but not limited to:

Potting Conductive Adhesive

SMT Adhesives

Silver Conductive Adhesives

Solder Paste

Sintering Paste

Flux

Silicone

LED Phosphor

Potting Materials

Hot Melt Adhesive

It includes the following microdispensing applications:

Microelectronics Manufacturing: Ideal for the precise dispensing of solder paste, adhesives and encapsulation materials in microelectronic assembly.

Optical Components: Ensures the precise application of coatings and adhesives in the production of optical devices.

Medical Devices: Highly suitable for sterile and precise dispensing during the assembly of medical instruments and equipment.

Semiconductor Manufacturing: Delivers sub-nanometer precision, which is critical for advanced semiconductor manufacturing processes.

Automotive Electronics: Suitable for high-precision dispensing tasks in the production of automotive electronic components and batteries for the electric vehicle industry.

Data Download

Data Download

0512-6729 6366

189 1261 4422