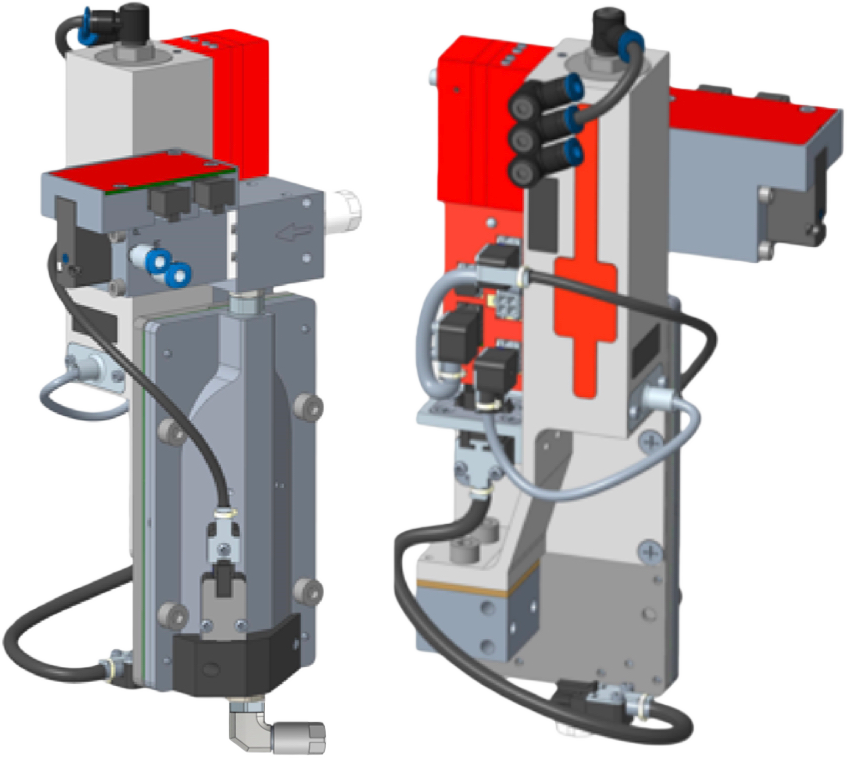

The PMB membrane pusher ensures constant-pressure adhesive supply. The customer pain point is that the feeding pump pressure must be precisely set and maintained constant during production. The PMB membrane pusher ensures constant pressure at the dispensing valve/dispensing head and guarantees accurate and stable dispensing results.

The membrane pushing pressure is derived from an independent oil/pneumatic tank, with pressure regulated by the dispensing valve and plastic diaphragm in between. When the adhesive is exhausted, the inlet valve opens, the membrane is refilled, and the pressure at the dispensing valve remains constant at all times.

In multi-production-line scenarios, one adhesive supply module can be connected to multiple membrane pushers. In this case, a normally closed shut-off valve module needs to be added to each membrane pusher for equal-pressure adhesive distribution to every piece of equipment.

|

|

| |

Data Download

Data Download

0512-6729 6366

189 1261 4422