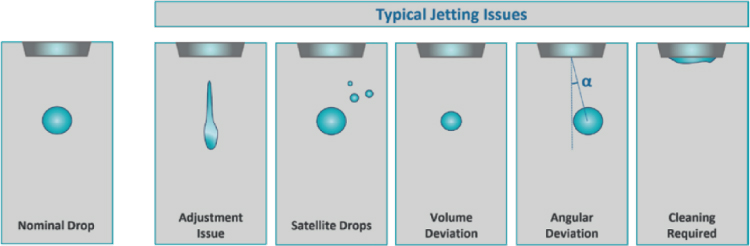

NanoStrobeX Droplet Detection Technology is a revolutionary optical system developed for inline dispensers and mounted on jet valve nozzles. Real-time droplet visualization has long been an expectation of dispensing engineers. Without this function, it is impossible to identify various issues such as volume variations of individual droplets, volume inconsistencies caused by different nozzles, satellite formation, and liquid residues on nozzles. With droplet visualization, engineers can observe the entire dispensing process.

Real-time monitoring is crucial for droplet behavior, as it is influenced by various environmental factors such as liquid viscosity, dispensing pressure, nozzle wear or damage, piezoelectric stack aging, temperature, and air currents. NanoStrobeX provides real-time images and comprehensive data analysis, including measurements of droplet volume, satellite droplet volume, and flight angle, enabling users to make precise adjustments to ensure optimal performance.

To achieve optimal dispensing results, users must correctly set the dispensing parameters of the jet valve, such as valve stroke, impact force, nozzle shape, and air pressure. Each parameter can exert a significant impact on droplet behavior. By monitoring droplet behavior in real time, users can gain deep insights into the droplet formation process and make corresponding adjustments to optimize the dispensing process, thereby improving precision and efficiency.

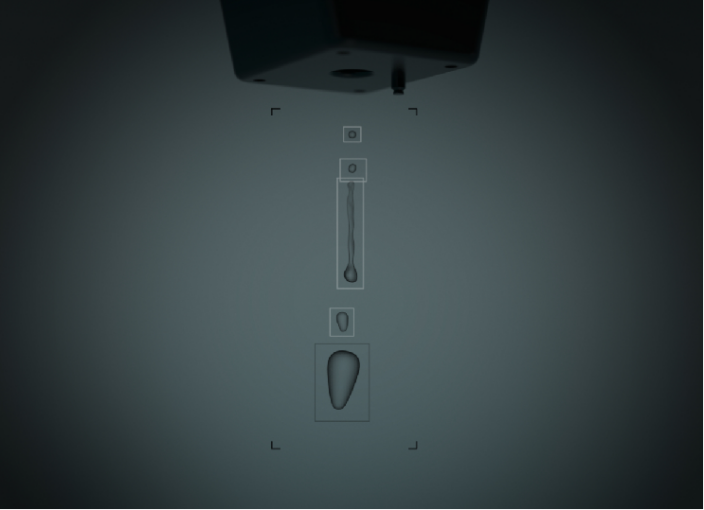

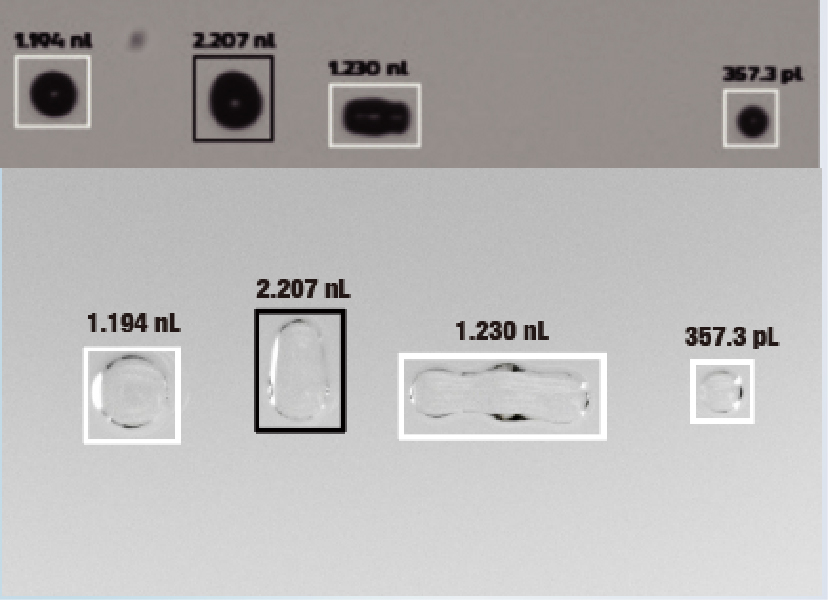

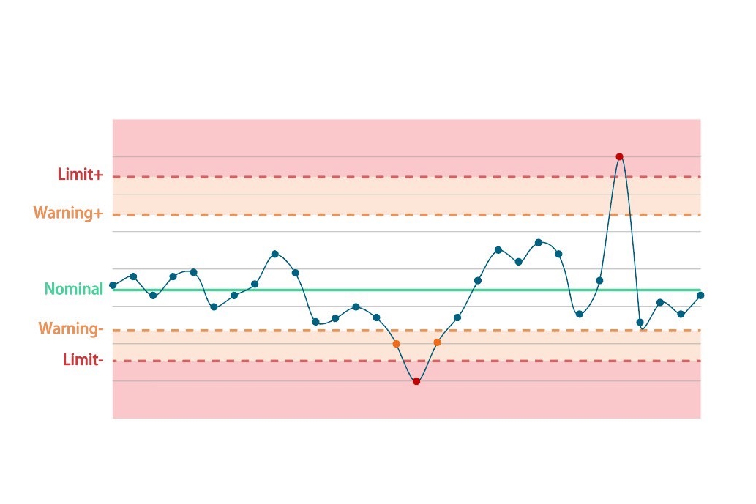

The key to precise dispensing lies in the consistency of dispensing volume. Variations in dispensing volume beyond specifications can compromise accuracy. Single droplet volume detection enables engineers to obtain real-time data on the volume of each individual droplet and collect historical data for analysis.

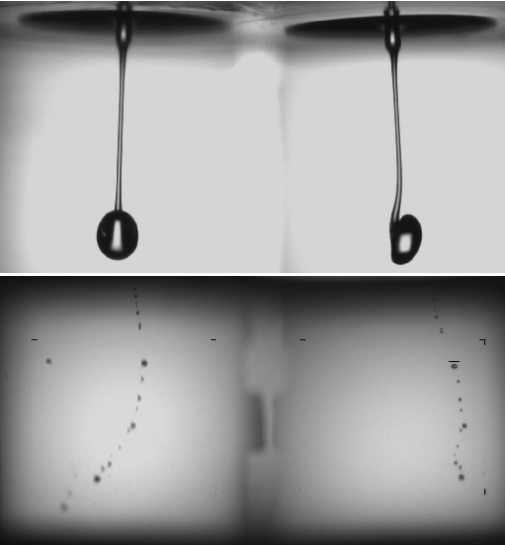

To improve production efficiency, it is sometimes necessary to dispense tiny micro-dots at frequencies up to 500Hz. The NanoStrobeX imaging system can capture clear droplet images at jetting speeds ranging from 200 to 500Hz, which can be used for inspection and production process analysis.

Droplet satellite formation can impair the precision of dispensing, and it can be caused by various factors such as excessively large dispensing gap, damaged striker pin, static electricity or air bubbles. Droplet monitoring enables engineers to monitor the occurrence of droplet satellites in real time and take timely corrective measures when necessary.

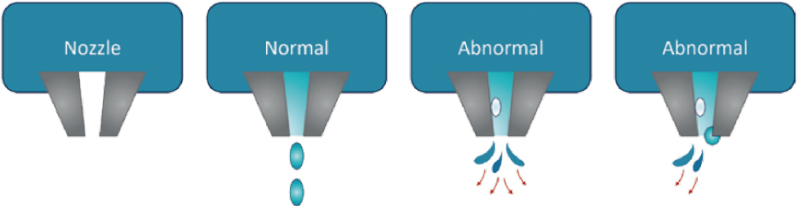

Whether it is jet dispensing or contact dispensing, a certain amount of adhesive may build up on the tip of the nozzle or needle. This can lead to variations in dispensing volume, and the nozzle or needle should be cleaned promptly. The NanoStrobeX imaging system enables users to detect the accumulated adhesive as soon as this situation occurs and take corresponding corrective measures.

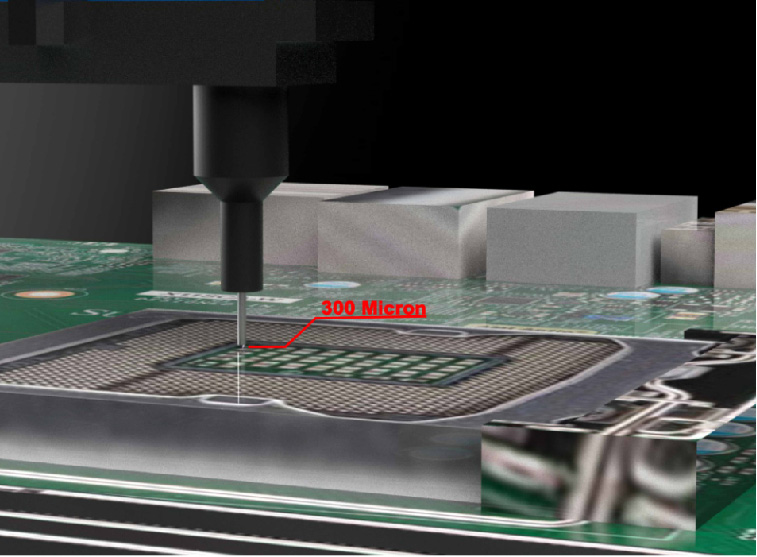

Precision dispensing usually requires the use of very small-sized needles, such as gauge 28, 30, or even 32. These small-sized needles are prone to bending due to improper packaging or collisions during the dispensing process, and a bent needle will lead to dispensing position deviation. NanoStrobeX can detect the bending angle of the needle to prevent dispensing position deviation, and can also detect cracks in ceramic needles.

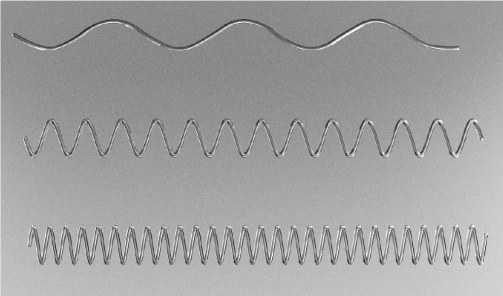

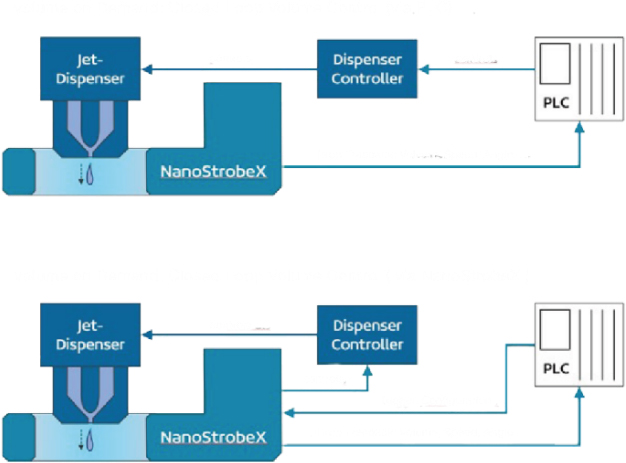

NanoStrobeX can provide valuable data for dispensing process analysis, including droplet volume, droplet frequency, droplet velocity, droplet dispensing angle, number of satellite droplets, satellite droplet volume, accumulated residue on the nozzle, droplet falling velocity, and deviation of droplet landing position. By analyzing the aforementioned data, engineers can reset all dispensing parameters of the jet valve—such as opening time, descent time, stroke level, dispensing gap and production line speed—to improve dispensing results in real time.

Droplet volume may change during the dispensing process due to various factors such as air bubbles, viscosity changes, nozzle damage, air pressure instability, and piezoelectric stack aging. NanoStrobeX is capable of automatically calibrating droplet volume via air pressure or piezoelectric stroke adjustment.

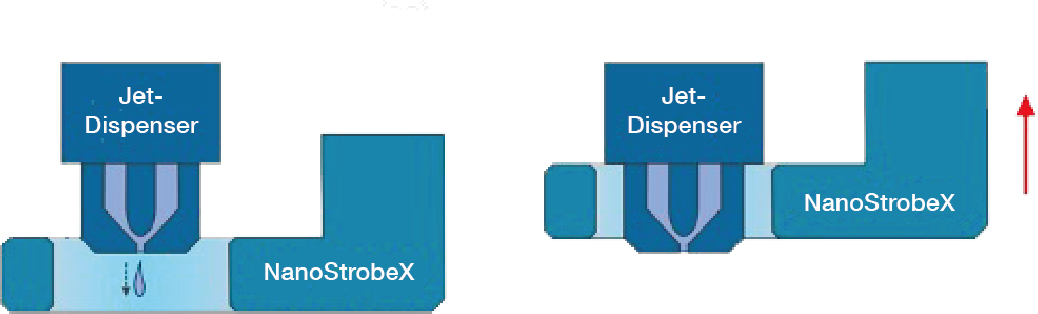

Some dispensing robots are equipped with an automatic nozzle cleaning design. To prevent the NanoStrobeX camera system from interfering with the nozzle cleaning process, NanoStrobeX can automatically lift up during cleaning.

The built-in WebGUI of the NanoStrobeX camera system enables users to obtain real-time droplet images and other analytical data via PC, laptop or smartphone anytime, anywhere.

As dispensing dots become increasingly smaller, the dispensing gap usually has to be correspondingly reduced to achieve the required pattern and positional accuracy while avoiding satellite droplets. Therefore, droplets do not form a perfect sphere before contacting the substrate. To address this challenge, Droptical has designed a camera with an angled viewing perspective and a special algorithm, enabling the droplet volume to still be calculated in real time.

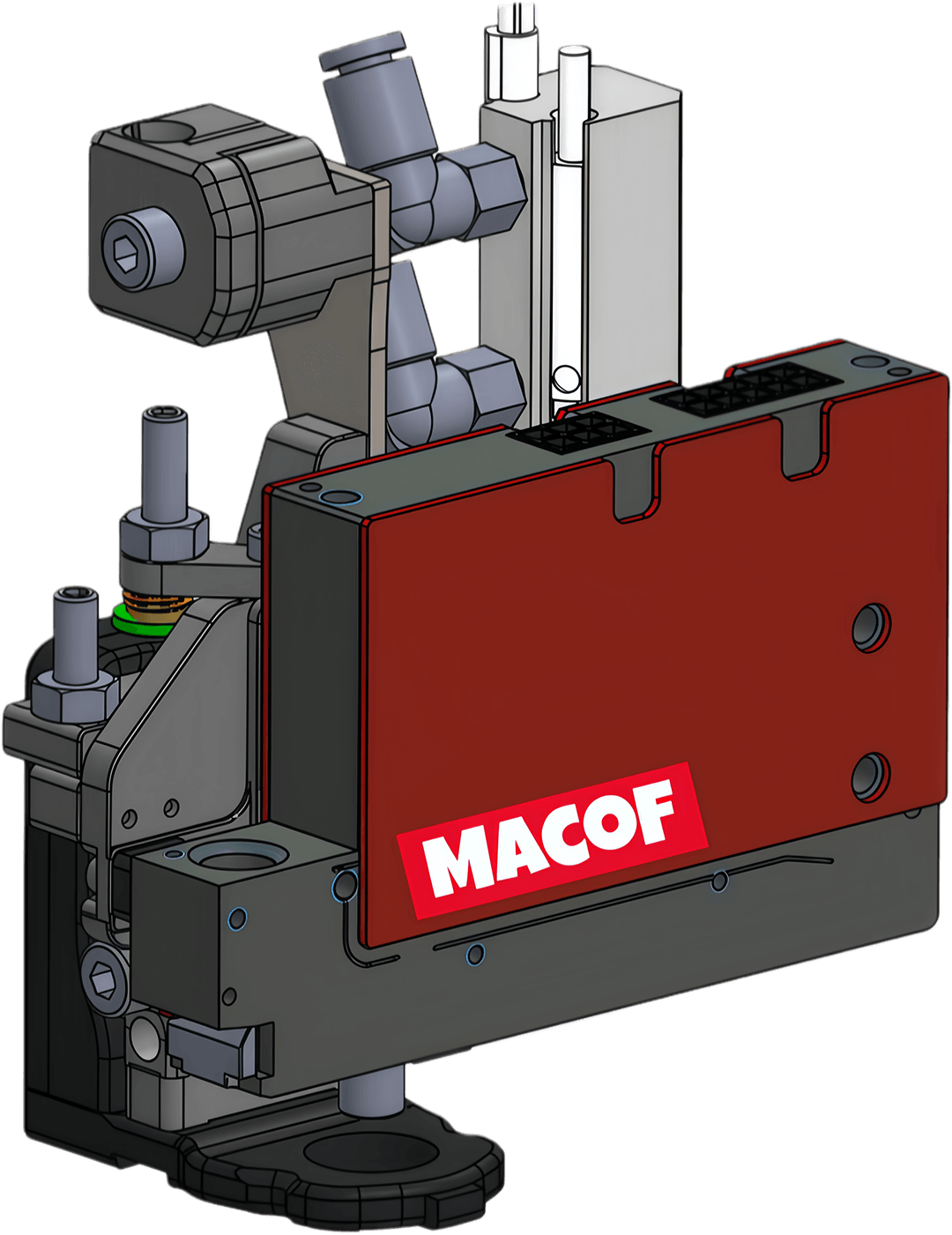

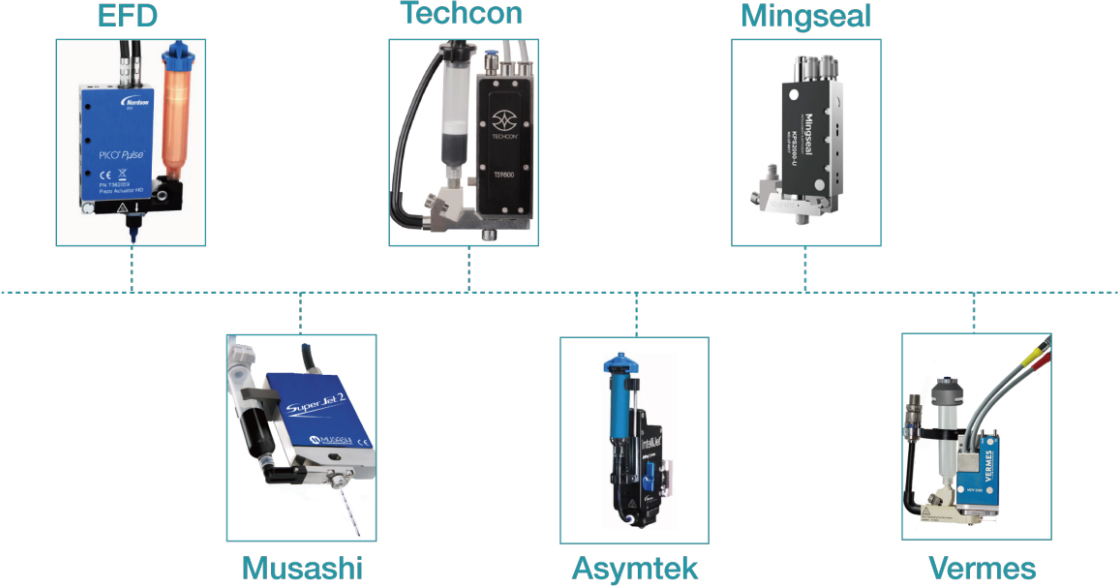

Including EFD, Asymtek, Musashi, Vermes, Mingseal, Protec, Techon, Fisnar and others, the NanoStrobeX camera system is available in different designs to meet the installation requirements of different jet valves.

UV Adhesives

Silver Paste

Underfill Epoxy

Silicone

Solvents

Solder Paste

Acrylics

Hot Melt Adhesives

Oils

Droplet Velocity: 0 – 4 m/s (Higher velocity optional)

Droplet Size: 125 μm in diameter (for 1 nl); 1500 μm (Z-dimension)

Detectable Volume Range: 0.2 nl – 50 nl (Smaller droplets optional) (Different optical units are required for various calculations)

Detectable Satellite Size: A few microliters or 5 μm in diameter

Droplet Angular Deviation: Max. 5° (in X and Y directions) (Angular tolerance is used as the criterion for judging result quality)

Repeatability: CPK 1.66, Tolerance 5%, Standard Deviation 0.5%

(Dependent on jet valve accuracy)

Pixel Resolution: 2.8 μm

Optical Resolution: < 2 μm

Field of View (W x H): 0.5 mm x 2.5 mm

Measurement Frequency: 50 Hz, 100 Hz, 200 Hz (> 200 Hz optional)

Measurement Gap (Z-dimension): Max. 3.5 mm

Camera Size (Thickness) (Z-dimension): 2.5 ~ 3.0 mm

Droplet Counting: Counts the number of droplets

Satellite Counting: Counts the number of satellite droplets

Data Download

Data Download

0512-6729 6366

189 1261 4422