Location:Home > VERMES Piezoelectric Jet Valve SeriesMDS3280

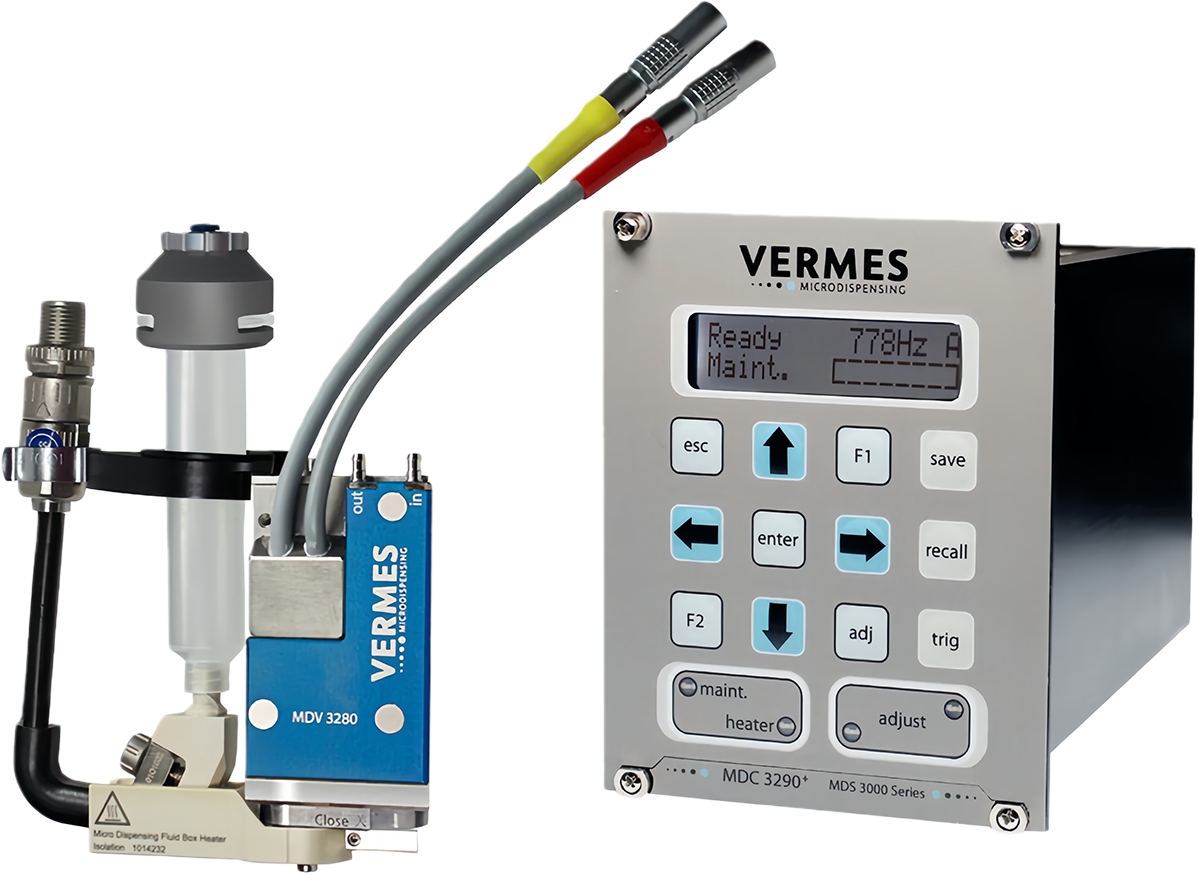

The high-precision VERMES MDS 3280 Series Microdispensing System integrates a number of advanced technologies, significantly boosting system performance.

Its highly flexible modular design is perfectly adaptable to various dispensing media.

The proprietary Quick-Release Fluid Cartridge enables flawless non-contact dispensing (without contacting the dispensing substrate) and facilitates rapid maintenance.

Proprietary Quick-Release Fluid Cartridge with built-in integrated heating block

Top calibration for quick setup

Easy operation and simple cleaning

Ultra-high precision, non-contact dispensing

Seamless integration into confined spaces

High-speed piezoelectric technology

Extremely wide application range

The proprietary Quick-Release Fluid Cartridge adopts innovative connection technology, enabling more flexible connection between the valve body and the fluid cartridge. The fluid cartridge features a zero-screw design; it can be removed from the valve simply by flipping the buckle, making it easy to operate and clean.

With outstanding dispensing performance, it can eject droplets with a diameter smaller than that of a human hair (150 μm) at maximum frequency, while maintaining extremely high droplet consistency and repeatability. This effectively improves productivity and reduces costs.

The MDS 3280 Series Microdispensing System is based on mature piezoelectric drive technology and boasts all the advantages of non-contact dispensing.

A key feature of the MDS 3280 Series is its brand-new valve body design, which ensures optimal system performance, cost-effectiveness, high production efficiency and excellent dispensing results with consistent, repeatable droplets.

The "Top Calibration" dispensing valve enhances user experience, with calibration screws located on the top of the valve for easier calibration operations.

Parameter settings can be adjusted while the system is in operation. In other words, during system runtime, parameters can be modified to adapt to changes in medium viscosity, dispensing patterns, dispensing quantity and other variables.

The fluid supply unit adopts an innovative, unique rotatable design, enabling the compact dispensing valve to perfectly handle multi-directional dispensing tasks. This system can be quickly and seamlessly integrated into various confined spaces.

Users can freely configure different nozzles and plungers. Plungers can be replaced directly at the work station without stopping the machine, featuring easy and convenient operation that effectively reduces downtime.

The fluid cartridge has a built-in nozzle heating block that saves space while maintaining a stable heating temperature. Under stable temperature and pressure control, dispensing results remain highly consistent until the medium in the fluid supply unit is completely exhausted.

The MDS 3280 Series All-Purpose Microdispensing System adopts cutting-edge microdispensing technology to achieve ultra-high precision dispensing, and is particularly suitable for media with high to ultra-high viscosity. The system can be widely applied to various fluids, such as:

SMT Adhesives

Potting Conductive Adhesives

Conductive Silver Adhesives

Solder Paste

Flux

Silicone

LED Phosphor

Underfill Materials

Hot Melt Adhesives

Microdispensing technology can be applied in the following fields:

Automation

Electronics

Mechanical Engineering

Automotive Electronics

Medical Care

Pharmaceuticals

Information Technology

Consumer Electronics

It is suitable for dispensing substrates of various shapes and surface materials.

Data Download

Data Download

0512-6729 6366

189 1261 4422